- Water Chiller - Oil Chillers - Cooling tower - Plastic Auxiliary Equipment - Hopper Loader - Hopper Dryer - Vertical Colour Mixer - Granulator

Gallery Contact Us

Industrial chillers are specialized cooling systems that's used in a different types of industrial applications to remove heat from liquids, such as water or oil.

Industrial chillers are specialized cooling systems that's used in a different types of industrial applications to remove heat from liquids, such as water or oil.

These systems are designed to cool industrial process fluids to specific temperatures, which is necessary for many manufacturing processes, such as plastic injection molding and metal industries.

Industrial chillers come in a range of sizes and designs, and have a many type of different specifications.

One important specification to consider when selecting an industrial chiller is its cooling capacity.

A chiller remove fluid is measurement in ton. For example, a 1-ton industrial chiller can remove 12,000 British thermal units (BTUs) of heat per hour.

Another important specification to consider is the chiller's flow rate.

This is the amount of fluid that the chiller can circulate through its system in a given period of time.

The efficiency of an industrial chiller is also an important specification to consider.

The coefficient of performance (COP) measured, which is the ratio of the cooling capacity of the chiller to the power input.

A higher COP indicates a more efficient chiller in Kolkata.

The type of refrigerant used in an industrial chiller is another important specification to consider.

CFCs and HCFCs are being phased mainly their negative impact on the ozone layer, therefore HFCs are becoming more common factor.

Another important specification to consider is the temperature range of the chiller. This refers to the range of temperatures at which the chiller can maintain the fluid.

Most industrial chillers are designed to maintain fluids at temperatures between 40 and 60 degrees Fahrenheit.

The noise level of an industrial chiller is also an important specification to consider.

A lower noise level is generally preferred.The type of compressor used in an industrial chiller is also an important specification to consider.

There are two main types of compressors used in industrial chillers: reciprocating and screw.

Reciprocating compressors use a piston to compress the refrigerant, while screw compressors use a screw-like mechanism.

Screw compressors are generally more efficient and reliable than reciprocating compressors.

Another important specification to consider is the size and weight of the chiller.

This will depend on the space available for the chiller and the weight capacity of the structure it will be placed on. Finally, the cost of the industrial chiller is an important specification to consider.

Industrial chillers can vary widely in cost, depending on their specifications and features.

It is very important to carefully consider all of the technical specifications of a chiller .

In summary, industrial chillers are an essential part of many industrial systems, providing a reliable and efficient way to cool fluids and maintain precise temperatures.

This thing needs to be watched very carefully consideration of key specifications such as cooling capacity, flow rate, efficiency, refrigerant type, temperature range, noise level, compressor type, size and weight, and cost can help ensure that the right chiller is selected for the specific application.

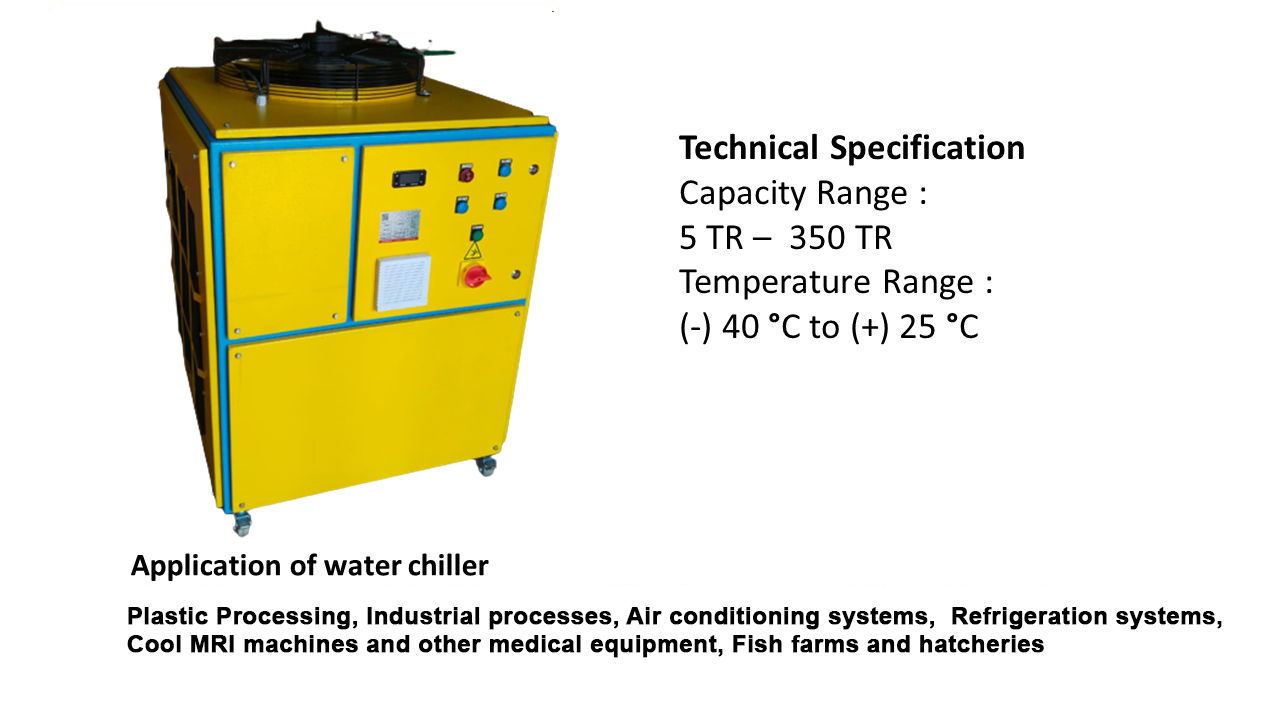

Application of water chiller :

Water chillers have a wide range of applications in various industries. Some of the most common applications include: